Before we get too fired up about the effects of high fuel prices, let’s put this in perspective, because when you do you’ll see that this is well within your control.

A contractor with annual sales of roughly $700,000 will rarely see more than 6% of sales going toward fuel. Most say it’s more like 4%, so let’s meet in the middle and use 5% as an example:

$700,000 x 5% = $35,000

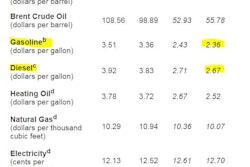

By mid-April, fuel prices had gone up roughly 40% since the start of the year

$35,000 x 1.4 = $49,000

Provided this contractor will burn the same amount of fuel, he’ll spend about $14,000 more than he would have spent had fuel prices stayed where they were at the beginning of the year. While this is nothing to sneeze at, it’s important to keep in mind that this is only 2% of this contractor’s revenue; hopefully not enough to drive him into the red. Regardless, there are several strategies that can help him recover that additional cost—and they can work just as well for you, regardless of the size of your operation.

Be selective with price increases

If you have written contracts with your customers, do not increase your prices on a percentage basis for all customers all at once. While this may appear to be the fairest way to spread your pain, it is probably not the smartest.

When you are looking at increasing your prices, focus on the bottom 10-20% of your clients, as opposed to your most profitable and loyal clients whom you want to keep happy. Identify those weaker accounts where you’re not making your target profit margins and start there. Chances are you’re not charging these customers enough in the first place, and if a modest price increase triggered by a spike in fuel costs is enough to encourage these customers to fire you, you might not want them as clients to begin with.

Fuel surcharges

The “fuel surcharge” is a more straightforward strategy that can also work very well. You simply add a line item to your service agreement that says something to the effect of, “This price is good until the price of fuel hits (insert dollar amount), at which time a fuel surcharge will automatically be added to your invoice.”

One upside to using fuel surcharges is that the client knows upfront that it could happen. Another upside is that this type of surcharge is almost always viewed as temporary by the consumer; if fuel prices go back down, the surcharge will go away. Generally speaking, consumers are very agreeable to things like this—and will not hold it against you.

Adjust equipment hourly rates

Savvy contractors have established hourly operating rates for each piece of equipment, and bill customers accordingly. It makes sense to adjust your hourly operating rates since your equipment is burning through the majority of your fuel.

For example, let’s say your hourly rate on a 60-inch zero-turn is $8/hour. With the way fuel prices have gone up, you might need to raise that rate to $9/hour. This is a logical way to recover your additional fuel costs because you are charging customers extra for the use of your fuel-burning trucks and equipment, as opposed to your labor force.

Reduce fuel usage

There are all sorts of things contractors are doing to reduce fuel consumption, such as: reducing truck warm-up and idling time, training crews to refrain from operating trimmers and blowers at full throttle, having managers travel in more fuel-efficient vehicles, and improving routing.

Since $4 gas first reared its ugly head three years ago, there have been some technological advances that give contractors additional tools to help conserve fuel consumption. For example, in 2008 there was not a commercial-duty truck with significant payloads that could get 15 miles per gallon. Today there is. I even test drove several electric-powered commercial-duty trucks at the Work Truck Show this past March. There are also propane-powered trucks on the market today, not to mention propane-powered mowers and other equipment from more than a dozen manufacturers.

Eliminate waste and reduce labor cost

We started off this article by pointing out how the average contractor spends anywhere from 4-6% of sales on fuel. Although by no means peanuts, this expenditure pales in comparison to your largest expense: labor.

Most landscapers spend at least 35% of sales on labor, with labor-intensive companies like lawn maintenance contractors spending more than 50% in many cases. Given this fact, one of the best ways to offset rising fuel prices is to find ways to increase productivity.

Remember that $700,000 contractor we used as an example earlier? He’s probably spending an additional $14,000 on fuel this year. How much could he save by increasing productivity 5%? Check out this example:

7 employees working 225 days a year = 1,575 days

The average employee wastes at least 6 minutes per day

That’s 9,450 minutes – or 157.5 hours

$20/hour for wages and benefits x 157.5 hours = $3,150

By simply finding ways to remove those six minutes of wasted time per day per employee, this contractor can recoup more than 20% of his increase in fuel expenditures.

Although nobody wants to pay more for fuel, being forced to search for ways to offset the effects of this rising cost of doing business could end up being a good thing for your company overall. So start searching right now.

![Gravely Pro Turn Mach One My23 Dsc03139 Edit 1200x800 5b2df79[1]](https://img.greenindustrypros.com/mindful/acbm/workspaces/default/uploads/2025/10/gravely-pro-turn-mach-one-my23-dsc03139-edit-1200x800-5b2df791.BucBnDoN22.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)