Without completely knowing their costs, landscape contractors can't possibly arrive at an accurate bid number. And without that, they can't possibly earn the profit they need to sustain their businesses.

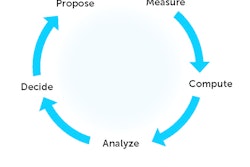

Contractors need a reliable, repeatable and consistent bidding system. By knowing all costs associated with each job, the bidding process will run more smoothly.

Information related to material prices and hourly labor costs should be readily accessible. Some contractors keep binders of information in their trucks. Others use management software back at the office, many times syncing up to a mobile device such as a smartphone or iPad. However you do it, having this information available on the fly is helpful. Not only can it help you to improve the accuracy of your estimating, but it can help speed up your estimating process. Remember, in many instances, the faster you can get an estimate into the prospective client's hands, the better your chances of getting the job.

Producing an accurate estimate requires two things: 1) Knowing how much it costs you to perform each task, 2) Knowing the exact parameters of the job you are bidding on.

Costs of each task

Do you know exactly how long it takes a crew to perform each service, down to each square foot and minute? If not, this is a good place to start.

Many highly profitable (more than 20% net profit) contractors bid jobs based on production rates. Standard "industry rates" do exist and can serve as benchmarks. But it's best to actually perform your own time studies. That's the only way to truly know how long it takes your employees to complete certain tasks.

Get a stopwatch, and go out to jobsites and perform time-and-motion studies on specific chores. Do this for every chore and piece of equipment your crews encounter. For example, how many square feet (or acres) per hour can your 60-inch zero-turn riding mower cut? Here's how to figure it out. What about your 48-inch intermediate walk-behind? And your stick edger? Walk-behind trencher? Skid steer with trencher? Fertilizer spreader? Aerator? Obviously, your equipment production list could go on and on—but that's a good thing.

You also should develop a production chart for the more manual labor-related tasks, such as planting a tree or laying sod. You need this type of detailed information to truly produce accurate estimates.

Accurate measurements

Many veteran contractors often boast that they've been doing this so long that they can simply eyeball a property and produce an accurate estimate. But that line of thinking can be a dangerous trap.

Highly profitable contractors have a couple of different systems they employ before putting a final number to an estimate.

One is the walk-through. As you walk through the entire site, take notes of current site conditions. Then give the prospective client a report of your findings. Doing so serves two purposes:

- All pre-existing conditions are outlined to eliminate false liabilities against your company during your contract period. Pre-existing conditions might include dead/dying trees or shrubs, turf areas in need of repair, damaged sprinkler heads, broken windows, potential hazards for mowing, and the current state of beds and mulch.

- You've now done your homework for future services you might be able to offer the prospective client down the road. For instance, maybe the client will call you back three months later in need of a mulch job. Because you've already taken measurements and filed the information, you can produce an estimate much more quickly and have a better chance of getting the job.

System number two is measuring for profit. Some contractors actually measure for variable site conditions, such as soil breakdown and how far crews will need to transport soil or other materials from the truck to the actual work location on the site. These things all need to be factored into the final estimate.

Factor in some profit

Once all the measurements and site conditions are taken, it's time to think about profit. Some contractors base the amount of profit they build into an estimate on a few things: Risk, size of job, market, and how badly they really want that given job.

For example, a fairly low-risk job might garner a modest profit margin of 15%, whereas a high-risk job might warrant 25%. If that same job is of normal size, it warrants 15-20% profit. If it's within your normal market area, that's 10-15%. But if it's outside of your normal market, you might beef it up to 25%. If you really want the job because it could lead to more work down the road, you might peg it for just 10% profit. On the other hand, if you could care less if you win the job, stick it at the high end with 25% profit.

However you determine it, add the four categories together and divide by four to see what the profit margin should be.

Then there's one more thing to consider: the client factor. How hard will the client be to work for? Some need more attention than others, and that costs time and money. Some are harder to please, which also costs time and money. So the client factor is definitely something to think about as you're putting your final estimate together.

![Doosan Bobcat Wacker Neuson Stack 2ec Js Pb V6e[1]](https://img.greenindustrypros.com/mindful/acbm/workspaces/default/uploads/2025/12/doosan-bobcat-wacker-neuson-stack2ecjspbv6e1.CPyyz8ubHn.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)