Silicosis. It’s a disabling and often fatal disease that can strike landscape crew members, even those as young as in their 20s. Yet many landscape company owners are unaware of the hazards of crystalline silica dust and how to protect their workers.

Silicosis, which often has no symptoms in its early stages, develops as a result of inhaling dust containing tiny particles of crystalline silica. Crystalline silica, which is a major part of the earth’s crust, can be found in many materials at landscape construction sites. Among these are soil, sand, brick, block, mortar and concrete. Other materials containing silica that may be present at general construction sites where your crews are working include cement board, roofing aggregate, and some drywall joint compounds.

Your crew members may be breathing in harmful silica dust and not even know it. That’s because the small particles of crystalline silica that get into the air are often not visible—and it can take 20 years or longer for the chronic form of silicosis to develop. In the meantime, though, as a crew member inhales the dust, silica particles can scar the lungs, causing the disabling, irreversible and incurable lung disease called silicosis.

The presence of silica in the lungs can also weaken the body’s ability to fight infections, so infectious illnesses such as pulmonary tuberculosis can develop. In addition, work-related exposure to crystalline silica can cause lung cancer and chronic obstructive pulmonary disease, and may be related to kidney disease and other adverse health effects.

Silicosis is a progressive disease, so removing a worker from the job does not stop its progression. As silicosis progresses, symptoms may include severe cough, chest pains, weight loss, fever, weakness, night sweats, shortness of breath, respiratory failure and/or death. (See “Resources for Employers” on page 26 for a link to the National Institute for Occupational Safety and Health (NIOSH) Health Hazard Review: Health Effects of Occupational Exposure to Respirable Crystalline Silica, where you can learn about other adverse health effects of occupational crystalline silica exposure.)

RISKY TASKS

Certain tasks performed by landscape crew members may generate crystalline silica dust. Among these are:

• Loading, hauling and dumping rock

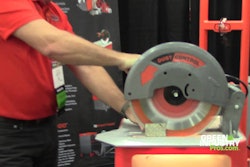

• Chipping, hammering, drilling, sawing and grinding concrete or masonry

• Grinding mortar

• Demolishing concrete or masonry structures

• Abrasive blasting (using sand as the abrasive or where the blasted surface contains silica, such as concrete)

• Dry sweeping or pressurized air blowing (concrete or dust)

• Using a jackhammer or chipper

• Using such mobile excavation equipment as a skid-steer loader, grader, bulldozer or truck

Specific jobs your crew members may be performing that could expose them to silica dust include constructing paver patios (sawing so the pavers fit together, especially circular patios because of the additional cuts that must be made), demolishing an old wall, building a fire pit or barbecue pit, cutting out curb using a concrete saw, or cutting off a piece of the end of a driveway.

Here is some more information about silicosis and silica dust:

• It is estimated that more than one million workers in the United States are at risk of developing silicosis each year.

• Although the number of reported silicosis deaths per year is about 160, the actual number is believed to be much higher. In addition, hundreds more workers each year become disabled as a result of the disease.

• NIOSH recently noted that workers between the ages of 15 and 44 continue to die of silicosis. This indicates that overexposures to silica dust are still occurring at worksites, despite the existence of Occupational Safety and Health Administration (OSHA) exposure limits. (See “Resources for Employers” for more information on OSHA’s Permissible Exposure Limits (PELs) for crystalline silica.)

• A failure to take steps to control workers’ exposure to silica dust can land your company in trouble with OSHA.

STEPS FOR EMPLOYERS

An important first step for all landscape contractors is to learn the applicable OSHA regulations. These include reporting any cases of silicosis among your workers on OSHA Form No. 300, Log of Work-related Injuries and Illnesses. Also, remember that depending on the task being performed, landscape contractors may be subject to either OSHA’s general industry standards or its construction standards. (See “Resources for Employers” for more information on OSHA’s silica-related standards, including links to information on OSHA’s respiratory protection standards.)

Here are some more steps to take:

• Determine whether your crews are at jobsites where silica dust may be present. Remember that silica dust may be generated by the work a general contractor or other subcontractors do.

• Implement a jobsite-specific safety and health plan. Make sure that your plan includes guidance on recognizing when silica dust may be present. Also, ensure that it includes measures you will take (engineering controls, personal protective equipment and work practices) to control or eliminate silica dust exposures and protect your workers.

• Conduct a safety and health assessment of each jobsite where silica dust may be present. Consider such engineering controls as wet drilling or wet sawing of materials containing silica, using a HEPA vacuum to clean up dust and debris, and requiring enclosed cabs on equipment used at the jobsites. NOTE: Be sure that you have a regular maintenance program for dust control systems and that you document in writing when maintenance was done.

• Determine whether crew members need respiratory protection. In order to do this, you will need to perform air monitoring of respirable crystalline silica exposures. Outside assistance is available to help you do this. Air monitoring is also important to make sure any engineering controls you have implemented are working. (See “Resources for Employers” for links to information on OSHA’s respiratory protection standards and NIOSH’s recommended exposure limits and respirator recommendations for crystalline silica.)

• Train your workers. Make sure they understand the potential hazards of silica dust, the importance of using appropriate engineering controls and respiratory protection, the importance of practicing “good housekeeping” at jobsites, and other steps they can take to reduce their risk of exposure to respirable crystalline silica.

• Make medical exams available to workers exposed to crystalline silica.

Resources for Employers

Free resources are available in both English and Spanish for landscape contractors interested in learning more about silica dust and silicosis. These include:

OSHA resources. For information on OSHA’s silica-related standards, visit: www.osha.gov/SLTC/silicacrystalline/standards.html. To link to other OSHA standards, visit: www.osha.gov, then click on “Regulations” at the top of the home page. Note: OSHA’s Permissible Exposure Limits for crystalline silica can be found in OSHA regulation 29 CFR 1910.1000, Table Z-3. Other helpful OSHA resources include: “Safety and Health Topics: Silica, Crystalline” at www.osha.gov/SLTC/silicacrystalline/index.html, the OSHA Silica eTool at www.osha.gov/SLTC/etools/silica/index.html, the OSHA eTool on Respiratory Protection at http://www.osha.gov/SLTC/etools/respiratory/index.html, the OSHA-PLANET (Professional Landcare Network) Alliance Landscaping and Horticultural Services Safety and Health Topics Page at www.osha.gov/SLTC/landscaping/index.html, and a publication entitled Controlling Silica Exposures in Construction at www.osha.gov/Publications/3362silica-exposures.pdf.

NIOSH resources. Visit the NIOSH “Safety and Health Topic: Silica” Web page at www.cdc.gov/niosh/topics/silica for silica-related information and to link to many other resources, including the NIOSH Health Hazard Review: Health Effects of Occupational Exposure to Respirable Crystalline Silica, www.cdc.gov/niosh/docs/2002-129/02-129a.html and the NIOSH Pocket Guide to Chemical Hazards, http://www.cdc.gov/niosh/npg where you can get more information on NIOSH’s recommended exposure limits and respirator recommendations. Other good NIOSH resources include a guide for workers entitled Silicosis: Learn the Facts at www.cdc.gov/niosh/docs/2004-108/default.html and the NIOSH “Safety and Health Topic: Respirators” Web page at www.cdc.gov/niosh/npptl/topics/respirators.

Silica Checklist for Employers.

http://hawaii.gov/labor/hiosh/sos/pdf/SILICA-CHECKLIST.pdf.

It’s Not Just Dust! What you should know about silicosis and crystalline silica.

www.cbs.state.or.us/external/osha/pdf/pubs/3301.pdf.

If It’s Silica … It’s Not Just Dust!

www.state.nj.us/health/silicosis/silicadust.shtml#masonry.

Other good resources include the OSHA On-Site Consultation Service, www.osha.gov/dcsp/smallbusiness/consult.html, which offers free and confidential advice to small and medium-sized businesses with priority given to high-hazard worksites; your state health department; and the electronic Library of Construction (for multilingual documents on silica), www.elcosh.org/docs/hazard/chemical_silica.html.

![Doosan Bobcat Wacker Neuson Stack 2ec Js Pb V6e[1]](https://img.greenindustrypros.com/mindful/acbm/workspaces/default/uploads/2025/12/doosan-bobcat-wacker-neuson-stack2ecjspbv6e1.CPyyz8ubHn.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Doosan Bobcat Wacker Neuson Stack 2ec Js Pb V6e[1]](https://img.greenindustrypros.com/mindful/acbm/workspaces/default/uploads/2025/12/doosan-bobcat-wacker-neuson-stack2ecjspbv6e1.CPyyz8ubHn.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)