While loading equipment in the yard might not be a challenge for those in the landscape, rental and construction industries, finding a level surface with plenty of room on a congested jobsite is another story. For safe loading in less-than-ideal conditions, many operators have found traveling axle trailers provide an efficient solution.

By matching traveling axle trailer specs and available features with their operational needs, companies can achieve a safer, more durable hauling solution that will also provide a better return on investment. Here are five features to consider for optimal loading in any condition.

1. Capacity

Required capacity is the starting point of any trailer purchase. Generally, traveling axle manufacturers offer models with 40- and 55-ton capacity, making them ideal for transporting a variety of equipment. If the intended load is mostly larger equipment, like excavators or pavers, pay close attention to the manufacturer’s 10-foot capacity rating. For mixed loads of small and mid-sized equipment, such as skid steers or lifts, the overall capacity will give a better indication of how many pieces of equipment can be safely transported. In industries such as landscape, rental and construction, many operators have found traveling axle trailers provide the ideal combination of features to increase safety and versatility.

In industries such as landscape, rental and construction, many operators have found traveling axle trailers provide the ideal combination of features to increase safety and versatility.

2. Loaded Deck Height

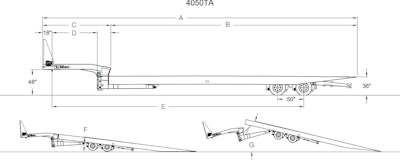

Another spec operators should keep in mind to limit permit costs and maximize productivity is loaded deck height. Within the U.S., legal load height is 13 feet, 6 inches, but operators will often encounter overhead obstacles that are lower. In these situations, a single inch can mean a difference of hours when it comes to getting from point A to point B and beyond. A traveling axle trailer with a loaded deck height of 36 inches provides optimal flexibility for transporting taller equipment such as excavators.

3. Construction

For loading in difficult conditions, such as muddy or uneven terrain, operators should look for a trailer with an equally rugged design. A rig’s piggyback cylinder provides power and traction for moving axles. While a 4-inch cylinder is common on most traveling axle trailers, models with a 5-inch cylinder provide 56% more push force to maximize axle operation.

Additionally, consider a 4-beam frame design that uses 4-inch I-beam crossmembers to increase longevity and versatility with mixed loads of smaller equipment. This design offers better deflection across the entire deck and a more even weight distribution compared to the commonly used perimeter frame which concentrates weight on only two outside beams.

4. Winch

For loading immobile objects, such as containers or dead equipment, a trailer with a 20,000-pound, direct-drive planetary winch with 6-function remote system provides more efficiency. This type of winch offers up to twice the loading speed of a more traditional worm gear model. A remote with a range of 150 feet increases the viable working area, allowing operators to choose the safest vantage point for loading and unloading. Additionally, a USB-chargeable remote offers added convenience over battery powered options. Generally, traveling axle manufacturers offer models with 40- and 55-ton capacity, making them ideal for transporting a variety of equipment.Talbert Manufacturing

Generally, traveling axle manufacturers offer models with 40- and 55-ton capacity, making them ideal for transporting a variety of equipment.Talbert Manufacturing

5. Additional Features

Finally, consider any extras, such as versatile tie-down options, for increased loading flexibility. Some trailers feature double keyhole tie-down slots on top of the outside beams and recessed in the center of the main deck. This provides a safe option for side-by-side loading of smaller equipment, such as skid steers, and is an important feature for landscape, construction and rental houses. Additionally, some manufacturers offer traveling axle trailers with a curbside toolbox for safe, convenient access away from oncoming traffic. This extra storage solution gives operators space to carry all the necessary chains and tie-downs for efficient mixed-load hauling.

Making the Right Choice

There’s a lot riding on your trailer decision. Selecting a traveling axle unit that maximizes safety and loading efficiency can be a complicated process. Working with reputable dealers and manufacturers can help you determine which features will best meet your operation’s hauling goals.

![U8kj71gt 720[1]](https://img.greenindustrypros.com/mindful/acbm/workspaces/default/uploads/2025/10/u8kj71gt-7201.8OyDyc124u.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)