Determining how much to charge customers when you utilize your trucks and equipment on a job can either be simple and straightforward or complex and potentially time-consuming. Similarly, the amount you ultimately come up with can either be accurate and reliable, or not so much.

On the simple side, some contractors over-simplify the estimating process in general, saying their price is "X dollars an hour" or "materials times two," for example. In scenarios such as these, equipment costs are rolled up into the formula with little to no thought. On the complex side, contractors try to pinpoint the precise cost of operating a piece of equipment—right down to the price they pay for a fuel filter.

Could there be an effective method somewhere in the middle that meets a contractor's objectives without taking a lot of time and/or requiring a degree in bean-counting? To answer that, first ask yourself the following question: Why do I want to charge customers for use of my equipment in the first place?

First of all, you want to recoup all of your equipment costs so you can properly operate and care for that equipment, and eventually replace it when the need arises. Secondly, if you need to use a certain piece of equipment on a certain job, it only makes sense that the given customer pay for it—as opposed to other customer(s) where you don't even need to use that piece of equipment, which is what happens when equipment costs are blindly rolled up into overhead or formulas such as "materials times two."

So given these two goals/objectives (recoup your equipment costs and fairly charge customers), how should you go about determining your hourly equipment rates?

Two components to the formula

1. Purchase Cost. First, take the price you paid for a machine (including taxes and interest, if applicable) minus the expected resale value, and then divide that by the number of hours you plan to put on the machine. Example: You pay $12k for a zero-turn mower, plan to keep it for 2 years (2,000 hours), and think you'll be able to sell it for $3k. That leaves you with $9k to recoup over the course of 2,000 hours, which comes to $4.50 an hour.

2. Operating Cost. Second, look at all of the costs associated with operating that piece of equipment for 2,000 hours. These include gasoline, maintenance items such as grease, oil and filters, replacement blades and tires, any other necessary service repairs, and things like insurance, taxes and licenses. Once you add up all of these costs, add a slight fudge factor of 10% to allow for the unexpected. Then divide that amount by the number of hours you plan to put on the machine. Example: All of those operating costs add up to $15,000; a 10% fudge factor adds another $1,500 ... so $16,500 divided by 2,000 hours comes to $8.25 an hour.

You then simply add your first calculation to your second in order to come up with your hourly rate. Using the above examples, that would be $12.75 an hour ($4.50 + $8.25).

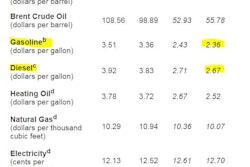

As you can see, the first calculation (purchase cost) is rather simple. The only tricky part is that you need to have a pretty good understanding of what you'll be able to sell your used equipment for when the time comes. On that note, you might not even want to bother factoring in a salvage/resale value; doing so will only drop your hourly rate by $1 to $1.50 at the most, anyway (see accompanying graphic).

The second calculation (operating cost) is obviously a lot more involved with many more components. Figuring all of them out requires the use of good historical data (i.e. hourly fuel consumption per piece of equipment, past service records to identify maintenance intervals and other service needs), along with current pricing information on things like fuel, oil, filters, etc. This second calculation also requires a good amount of your time. As an extremely busy owner/operator, is this really how you want to spend your time?

Quit beating your head against the wall

Recognize one thing: Regardless of what you'd paid for a mower, tractor or any other piece of equipment, the operating costs won't change. So that second calculation is, for all intents and purposes, set in stone and capable of being applied to other like pieces of equipment in your fleet. For example, all riding mowers need new blades, tires, oil and filters at similar intervals.

After playing around with this second calculation in an Excel spreadsheet, we can tell you that, generally speaking on a commercial mower, the hourly operating cost over a life of 2,000 hours is going to be right around $7.50 to $8.50 an hour. NOTE: You'll want to separately calculate the "average hourly operating cost" for a skid steer, 21-inch mower, leaf blower, string trimmer, etc. because those pieces of equipment will be much different than your large walk-behind and riding mowers, obviously.

A sudden spike in fuel prices could throw your operating costs out of whack, which is why it might be best to error on the side of caution and factor in a bit higher fuel cost, which we've done ($3.50 a gallon vs. current average of $2.80); doing so only bumps up the hourly rate by a dollar or so anyway.

A major repair bill could also throw this second calculation out of whack. That's why we apply that 10% fudge factor to the operating costs. That's also why it's not a bad idea to get in the habit of replacing equipment as soon as it's out of warranty. Then you can continue to budget for predictable maintenance and service procedures, but not worry about getting blindsided by an unexpected repair bill in the middle of the season.

Remember, the longer you keep a piece of equipment in operation, the lower your per-hour purchase cost will be. However, your per-hour operating cost then starts to go up as more repairs become necessary. So your overall hourly cost only lowers by a buck or two, at best. Furthermore, the headaches and hassles associated with older equipment could far outweigh that.

And what about your customers? Will they really care about—or even notice—that you're charging $1 or $2 an hour more for your mower, trencher, skid steer, or whatever piece of equipment you're using? I mean, how many hours per week/month are you using it on their job? For example, if you're running your mower three hours a week on their property, that's 12 hours a month. So we're talking about $12 to $24 more. Will 20 bucks really put you at risk of losing the job?

"In most cases, it is not the cost of equipment that may cost you a job," says Gary Goldman, a former contractor who has also been a management consultant to the landscape and pavement industries since 1985. "It is most often the lack of a consistent estimating process that accurately reflects your crews' production times and efficiency rates."

You just have to play the situation at hand, just as you do in any bidding scenario. Part of playing the situation at hand is understanding how much you'll be using your different types of equipment on the job, and how much it costs you to operate that equipment. By calculating some straightforward, yet reliable hourly rates that help you to safely recover your costs and still remain competitive, you can put it all together to create prices that work for your customers, your equipment and your bottom line.