Estimating can be a difficult task, there are a number of different factors that should be considered when setting up prices for lawn care and landscape services. Some companies can fall into the trap of pricing every package the same, not taking into account the different variables that they will inevitably come across.

Tony Bass, a featured speaker and business consultant, is the founder, inventor and president of Super Lawn Technologies in Fort Valley, GA. Super Lawn Technologies is a business and manufacturing company that serves lawn, landscape and contracting companies across North America. Bass says many companies go wrong when they fall into the habit of “guesstimating” rather than giving proper estimates.

“Estimating is absolutely a science and it starts not just by walking by a property or by talking to the customer, but by taking accurate field measurements first. I always know when I’m dealing with a true professional in this industry when they’ve got the measuring wheel in their pickup truck and it’s been beat up. A measuring wheel is a very important tool. I would say that the measuring wheel is even more important than your power equipment because it’s where pricing starts, with accurate field measurements.”

Another idea is that an estimate can be done just by looking at a property, but Bass says that even veterans of the business can run into problems with this. Cutting corners when estimating only cuts profits.

“Today in contracting, one out of five jobs goes bad. And when I say it goes bad, it actually cost the company money to complete the project. That means that the contractor who took on that job would have been better off to just write the customer a check after their initial appointment.”

Implementing a rate-based estimating system

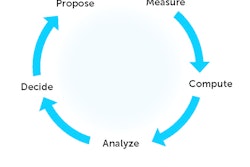

Bass’ method is what he calls production rate-based estimating system; his method involves using the accurate field measurements combined with knowledge of equipment and man-hours that are needed to accomplish the job.

“Say you’re going to price a mowing job to start with. A mowing job would have a number of precise measurements that you can collect to help you accurately plan for the cost of labor, materials, equipment and sub-contractors on that job. It starts with measuring the square footage of the lawn area that you will be mowing. The second measurement would be the square footage of the lawn that you will need to string trim. And then you will measure square footage of the lawn where you have different size lawn mowers in the areas.”

The size of the property is variable along with the areas of the lawn that may be hard to maneuver in. Where some places will allow for a 60-inch mower, others may have obstacles that require a 36-inch mower. An accurate estimate includes differences in specific customers’ properties.

“If you’re going to provide a shrub pruning service I will count the actual number of shrubs and I will classify them as in one of three categories—small, medium and large. With each different category of shrub I will allocate a different amount of pruning time.”

When it comes to edging, weeding, mulching and even in the end when you use your blower to clear off all hard surfaces, it’s important to think about the time that it will take to allocate that job and the manpower needed to complete it. Classifying every job is ineffective because you fail to account for variables you see in site conditions like sloped areas, flat areas or rough brush.

“I’ve never seen two jobs alike, it takes a unique focused approach to collecting good field measurements so you know exactly what equipment to assign to that job.”

A part of the estimation process that is often overlooked is the productivity of a company’s employees and the rates at which equipment can perform.

“The companies that are truly profitable in this industry are those that know their numbers. They know their production rates, which are simply the amount of work that you can get out of a machine or a person. That varies as jobsite conditions change.”

Bass says that while most people know that production rates are key to making money, problems arise when companies invest in equipment before knowing their production rate. They then face that as equipment is upgraded, their job rate then changes as well.

“Just say that you’re providing an irrigation service. I remember early in my career we had a walk-behind trencher. A walk behind trencher can consistently, in our area in average soil conditions, open up a 4-inch wide ditch that is 12-inches deep. We could open up 100 linear feet per hour,” says Bass. “One year we changed machines; we invested in a more highly productive machine. Our irrigation rate changed immediately because we were opening up 200 linear feet per hour, a 6-inch wide trench and it was more like 18 inches deep. We were displacing more soil a whole lot more quickly, and what does that do? That actually lowered our cost of doing business.”

Distinguishing Conditions and Cost of Different Jobsites

Rather than having three production rates—high, medium and low—there are six that should be taken into account. Companies should evaluate commercial and residential landscapes differently.

“Pricing work is an art where estimating is a science. So the art of convincing someone to choose your company over a competitive company is simply your ability to create awareness of you providing a better value.”

With changes in the economy, it is important to have some flexibility in pricing. Bass noticed, several years ago, that companies that refused to change their prices lost out on jobs. On the other hand, remaining flexible with prices allows for good relationships and a strong customer base.